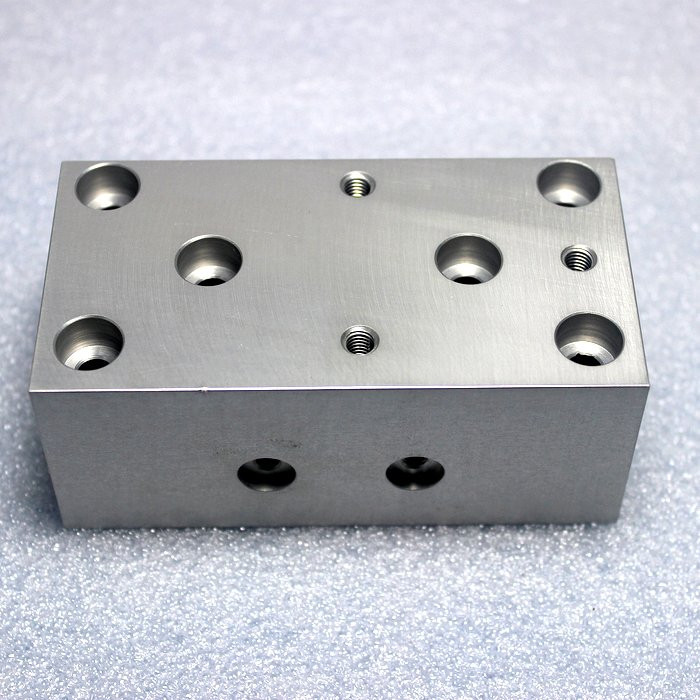

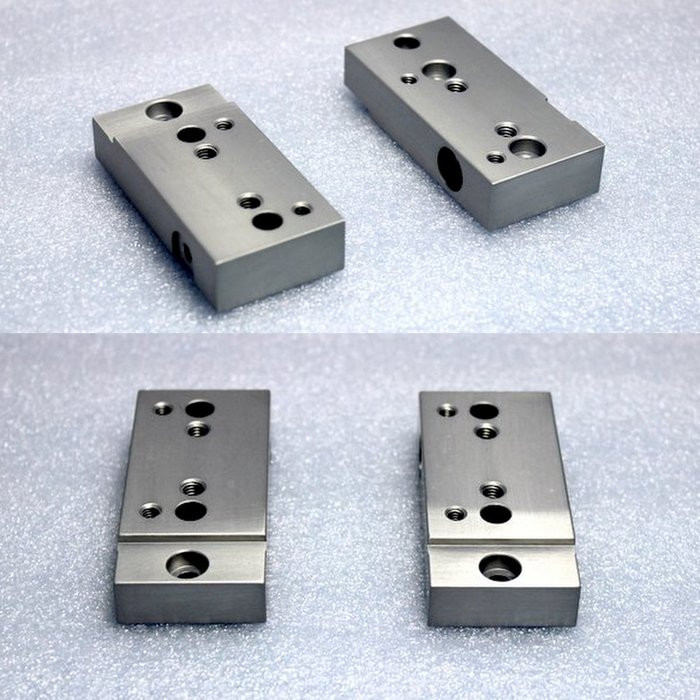

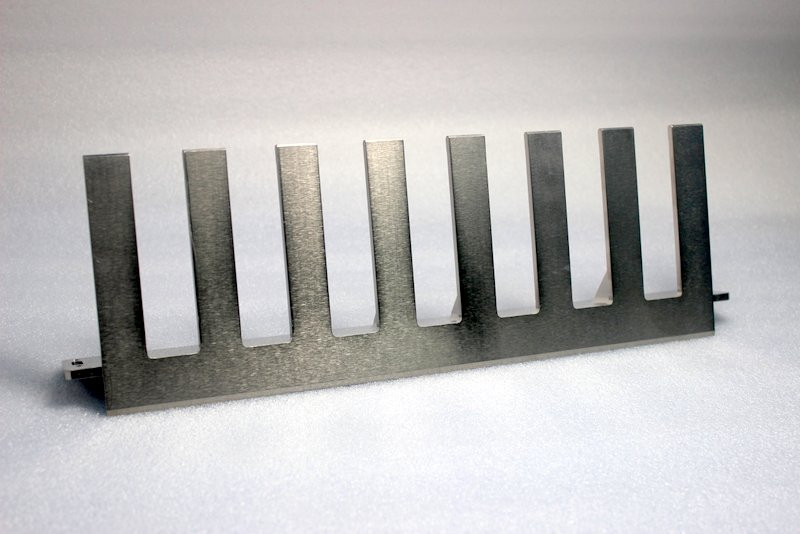

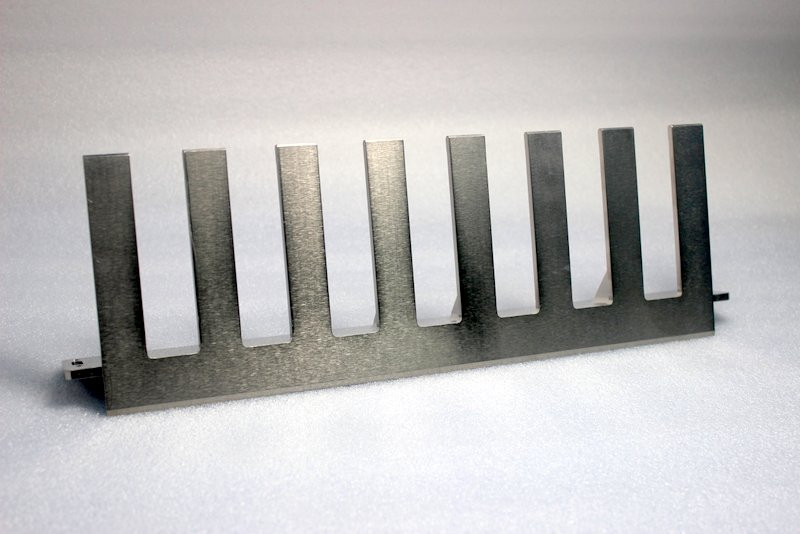

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

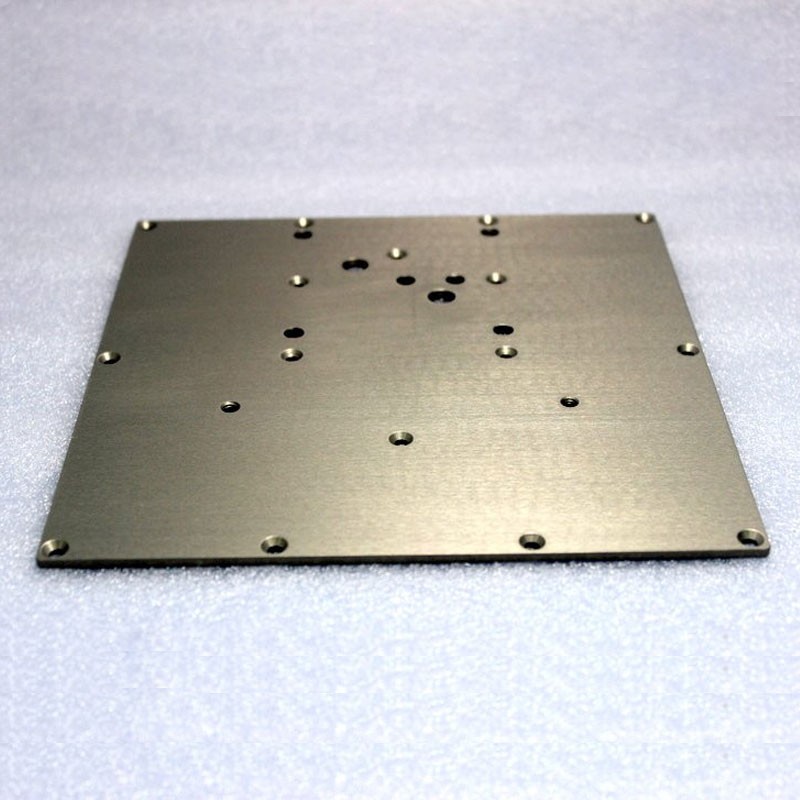

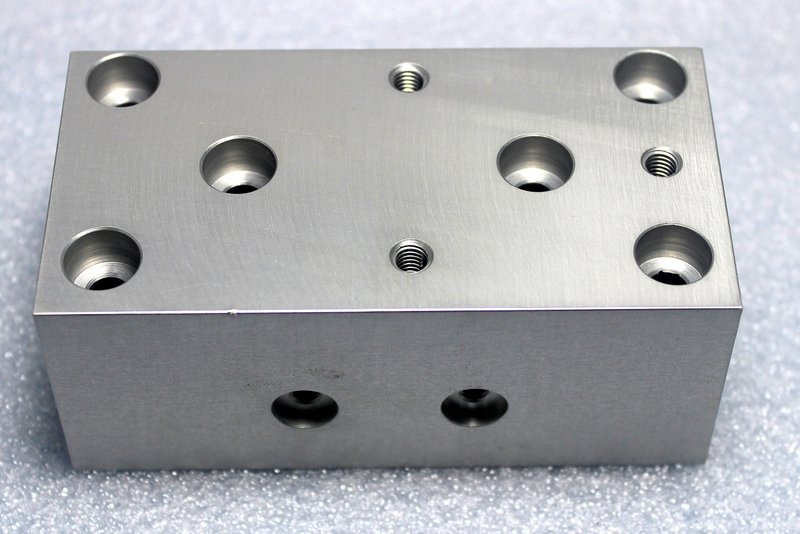

Surface treatment is a process method to artificially form a surface layer on the surface of the substrate which has different mechanical, physical and chemical properties from the substrate. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For the metal castings, our common surface treatment methods are mechanical polishing, chemical treatment, surface heat treatment, spraying surface, surface treatment is to clean the surface of the workpiece, cleaning, deburring, deoiling, deoxidizing skin.

Product Description

Stainless steel polishing as a mature surface treatment method, has been widely used, polishing can further improve the corrosion resistance and bright effect of stainless steel.

Chemical polishing of stainless steel fittings.

Chemical polishing in addition to get physical, chemical cleanliness of the surface, but also remove stainless steel parts surface mechanical damage layer and stress layer, get mechanical cleanliness of the surface, which is conducive to prevent partial corrosion of parts, improve mechanical strength, extend the service life of parts.

The role of electropolishing stainless steel accessories

A thick film with high resistivity is formed on the surface of stainless steel fittings. The thickness of the thick mucous membrane on the surface of the product is different, and the current on the anode surface is unevenly distributed. The micro bump has high current density and fast dissolution, which makes the burr on the surface of the product or the micro bump dissolve first and reach leveling. Depressions have low current density and slow dissolution. Due to the different distribution of current density, the surface of the product is continuously formed and dissolved at different rates. The anode surface is undergoing two opposite processes at the same time, film formation and dissolution, passivation film is constantly generated and dissolved, so that the surface of stainless steel accessories is leveled, to achieve a highly smooth and shiny appearance, to meet the purpose of stainless steel accessories surface polishing finishing.

He Xiang provide metal precision machining services of non-standard to customers in a wide range of industries, from selection of raw materials and process methods, to surface treatment and safety shipping.

Welcome customers to consult.