Medical Device Parts

-

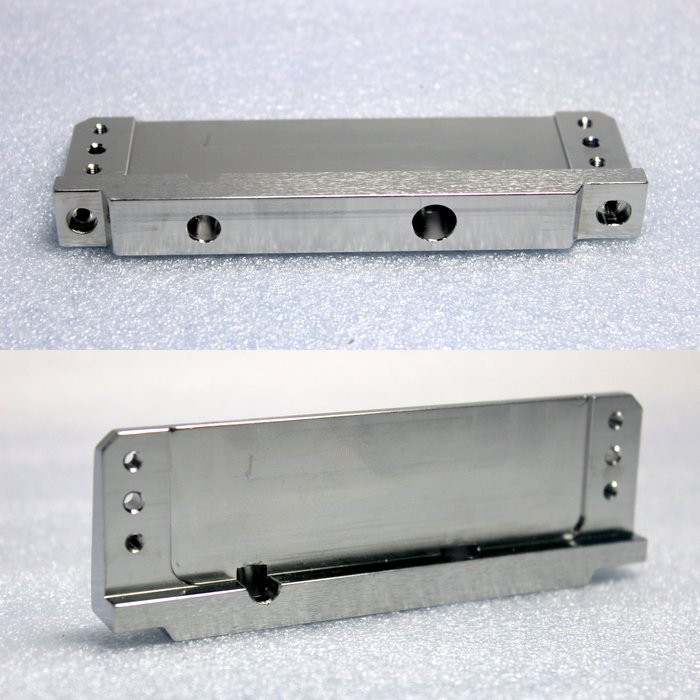

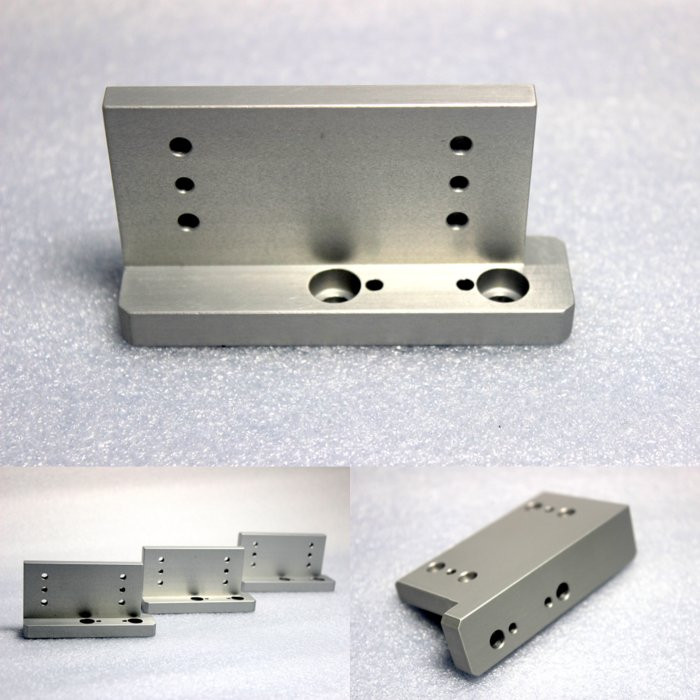

Milled Parts High Precision Parts

Medical accessories processing advantage lies in the medical accessories processing center.

Send Email Details

Medical parts processing center from the development of CNC milling machine. The biggest difference with CNC milling machine is that the machining center has the ability to automatically exchange machining tools, through the installation of different USES of tools in the tool library, can change the spindle machining tools in a clamping through automatic tool change device, to achieve a variety of machining functions.

Hexiang Precision Machinery Ltd has mature production experience for all kinds of mechanical processing in medical field, welcome customers to come to consult and cooperate. -

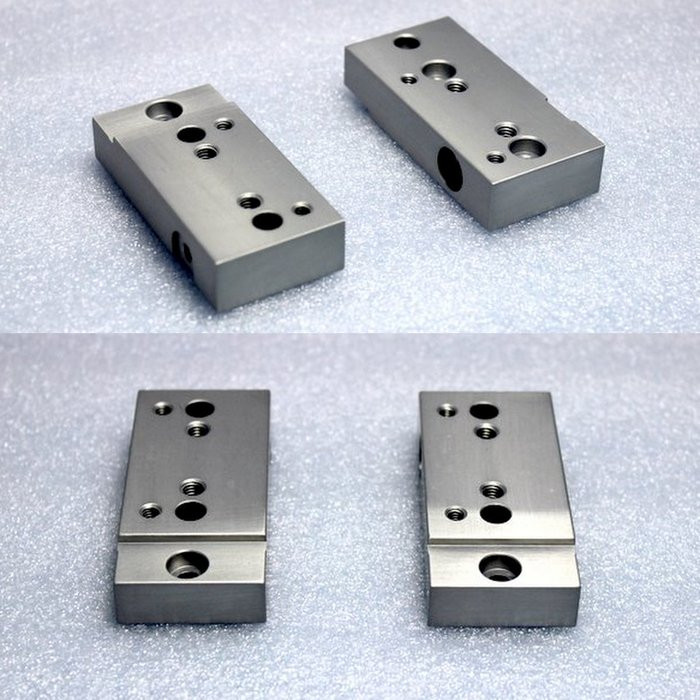

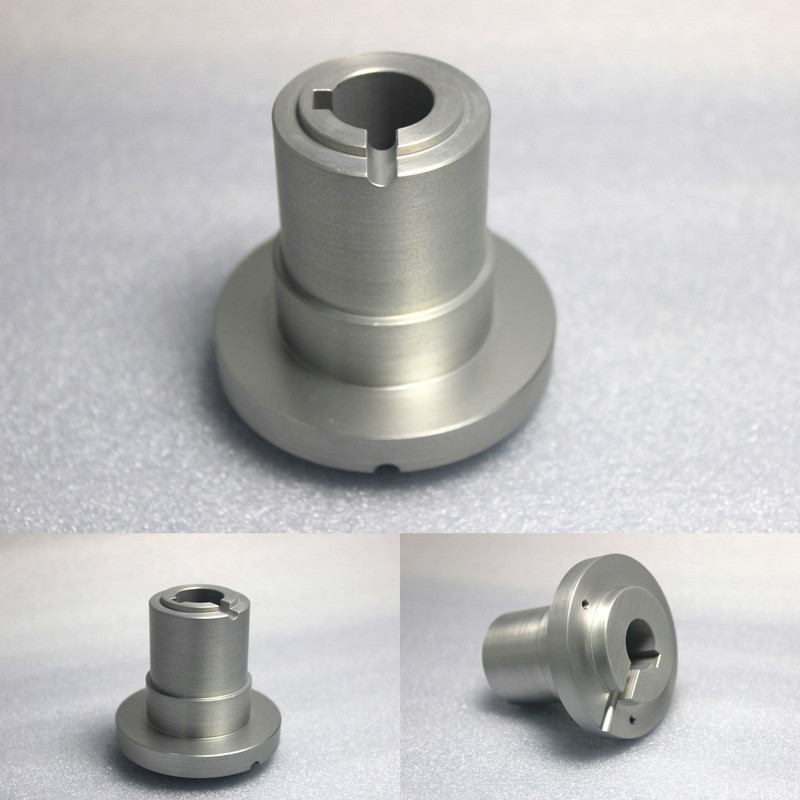

CNC Milling Components Stainless Steel

Medical accessories processing advantage lies in the medical accessories processing center.

Send Email Details

Medical parts processing center from the development of CNC milling machine. The biggest difference with CNC milling machine is that the machining center has the ability to automatically exchange machining tools, through the installation of different USES of tools in the tool library, can change the spindle machining tools in a clamping through automatic tool change device, to achieve a variety of machining functions.

Hexiang Precision Machinery Ltd has mature production experience for all kinds of mechanical processing in medical field, welcome customers to come to consult and cooperate. -

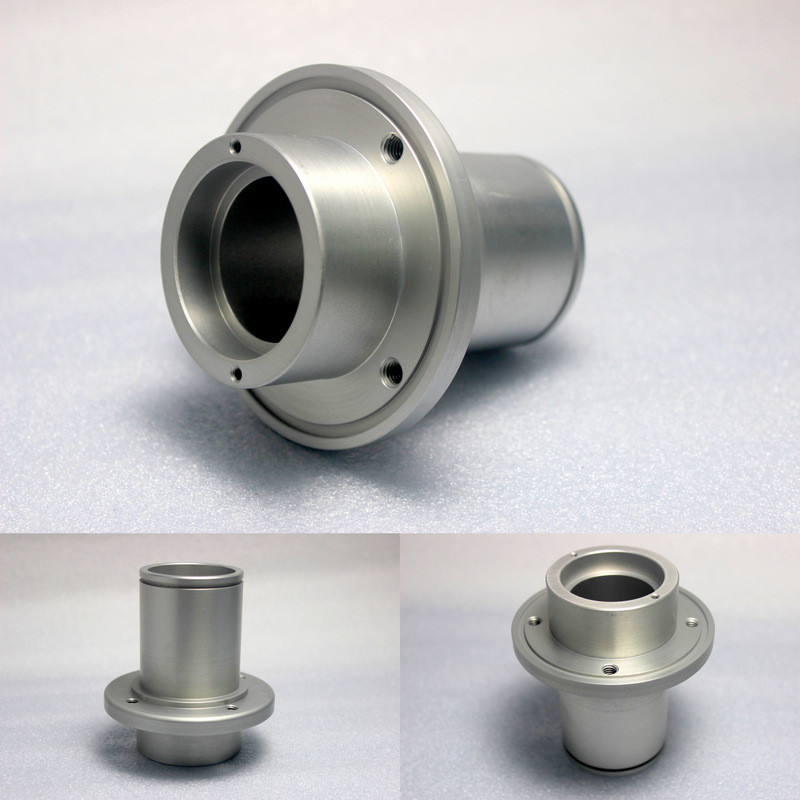

CNC Turning Components Aluminum Machining

Medical accessories processing advantage lies in the medical accessories processing center.

Send Email Details

Medical parts processing center from the development of CNC milling machine. The biggest difference with CNC milling machine is that the machining center has the ability to automatically exchange machining tools, through the installation of different USES of tools in the tool library, can change the spindle machining tools in a clamping through automatic tool change device, to achieve a variety of machining functions.

Hexiang Precision Machinery Ltd has mature production experience for all kinds of mechanical processing in medical field, welcome customers to come to consult and cooperate. -

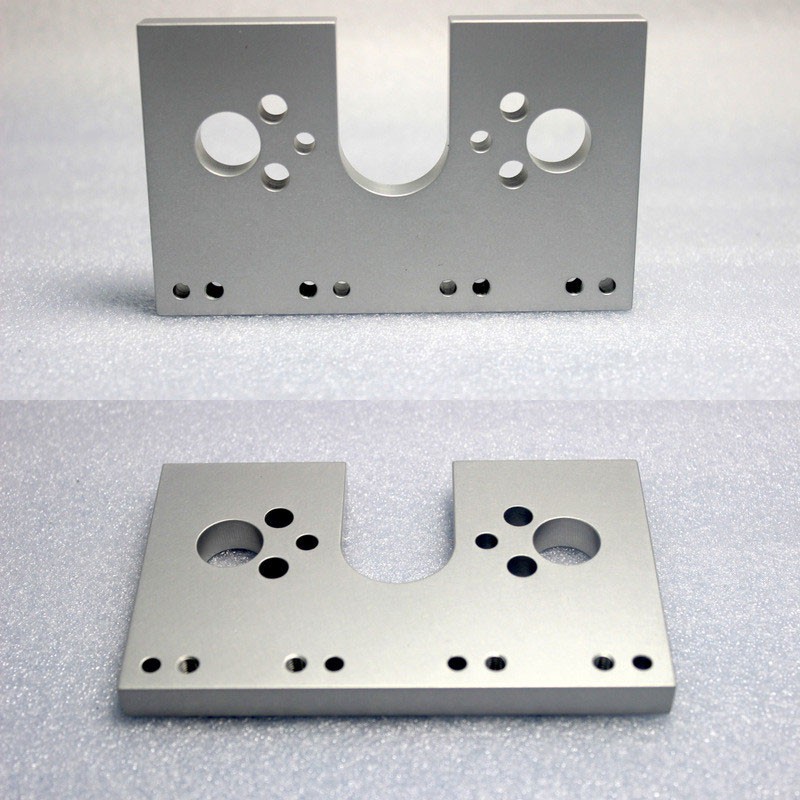

CNC Turning Components Custom Parts

Custom, cost-effective machining solutions

Send Email Details

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

Hexiang provides one-stop customized medical parts processing service, from raw materials to production and delivery of quality control, to ensure customer satisfaction is the first element of our service. -

Hot

CNC Milled Components Aluminum Machining

• Aluminum is light; its density is only one-third that of steel.

Send Email Details

• Aluminum is resistant to weather, common atmospheric gases, and a wide range of liquids.

• Aluminum can be used in contact with a wide range of foodstuffs.

• Aluminum has a high reflectivity and, as a result, is employed in a number of decorative applications.

• Aluminum alloys can equal or even exceed the strength of normal construction steel.

• Aluminum has high elasticity, which is an advantage in structures under shock loads.

• Aluminum keeps its toughness down to very low temperatures, without becoming brittle like carbon steels.

• Aluminum is easily worked and formed; it can be rolled to very thin gauges.

• Aluminum conducts electricity and heat nearly as well as copper.

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order -

Milled Parts Precision Machining Parts

Medical accessories processing advantage lies in the medical accessories processing center.

Send Email Details

Medical parts processing center from the development of CNC milling machine. The biggest difference with CNC milling machine is that the machining center has the ability to automatically exchange machining tools, through the installation of different USES of tools in the tool library, can change the spindle machining tools in a clamping through automatic tool change device, to achieve a variety of machining functions.

Hexiang Precision Machinery Ltd has mature production experience for all kinds of mechanical processing in medical field, welcome customers to come to consult and cooperate. -

Turned Parts Stainless Steel Parts

Medical stainless steel: (18-10) : +18% chromium +10% nickel, [1] to make it more durable and corrosion resistant, no metal ions precipitation, this stainless steel is called 18-10 stainless steel. Due to its durable and complete nature, it is mainly used in the manufacture of medical devices and tableware.

Send Email Details -

Hot

Milled Parts Stainless Steel Parts

Advantages of stainless steel:

Send Email Details

1. High strength, good plasticity and toughness.

2. Uniform material and high working reliability.

3. Steel is weldable.

4. Steel has no leakage, easy to make a closed structure.

5. According to different strength requirements, steel parts are widely used in various industries. -

Turned Parts CNC Precision Machining

CNC processing has the following advantages:

Send Email Details

1. Reduce the number of tooling greatly, and do not need complex tooling to process parts with complex shapes. If you want to change the shape and size of the parts, you only need to modify the parts processing procedures, which is suitable for the development and modification of new products.

2. The processing quality is stable, the processing accuracy is high, the repetition accuracy is high, and it can meet the processing requirements of aircraft.

3. The production efficiency is higher in the case of multi-variety and small batch production, which can reduce the time of production preparation, machine tool adjustment and process inspection, and also reduce the cutting time due to the use of the best cutting quantity.

4. It can process complex profiles which are difficult to be machined by conventional methods, and even some parts which can not be observed.