Medical stainless steel: (18-10) : +18% chromium +10% nickel, [1] to make it more durable and corrosion resistant, no metal ions precipitation, this stainless steel is called 18-10 stainless steel. Due to its durable and complete nature, it is mainly used in the manufacture of medical devices and tableware.

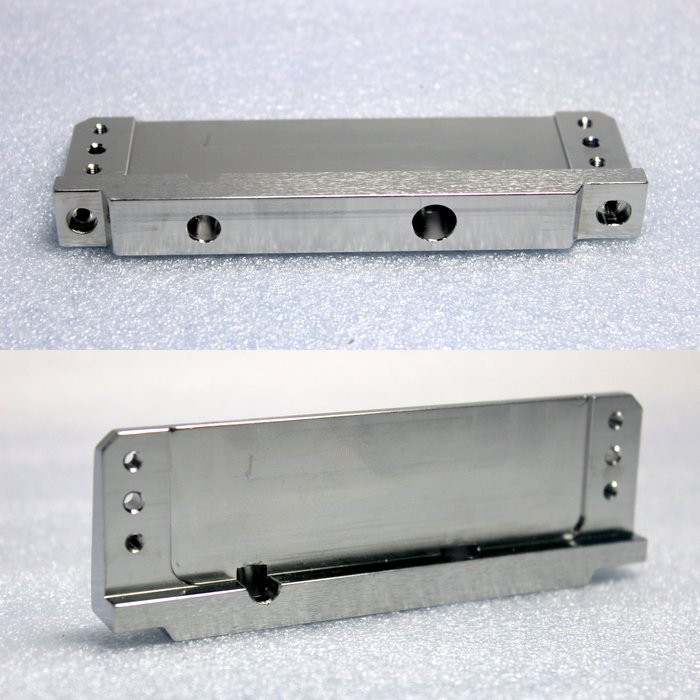

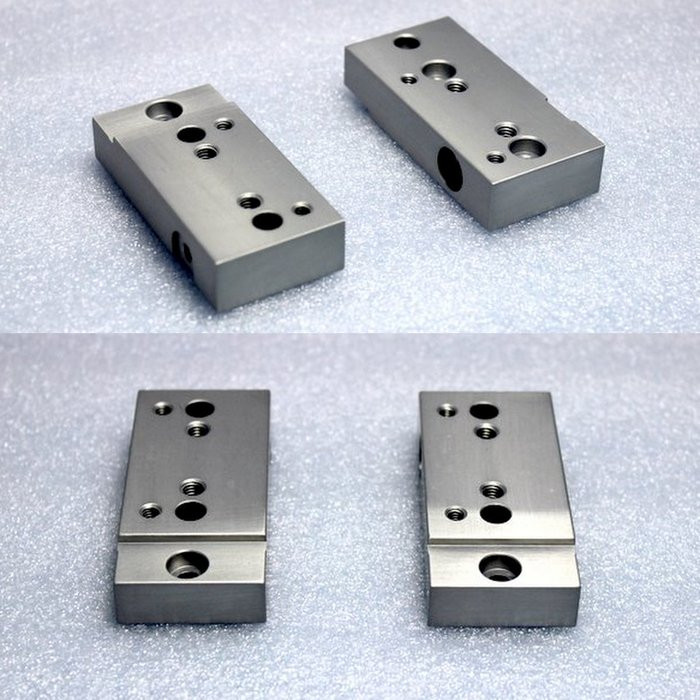

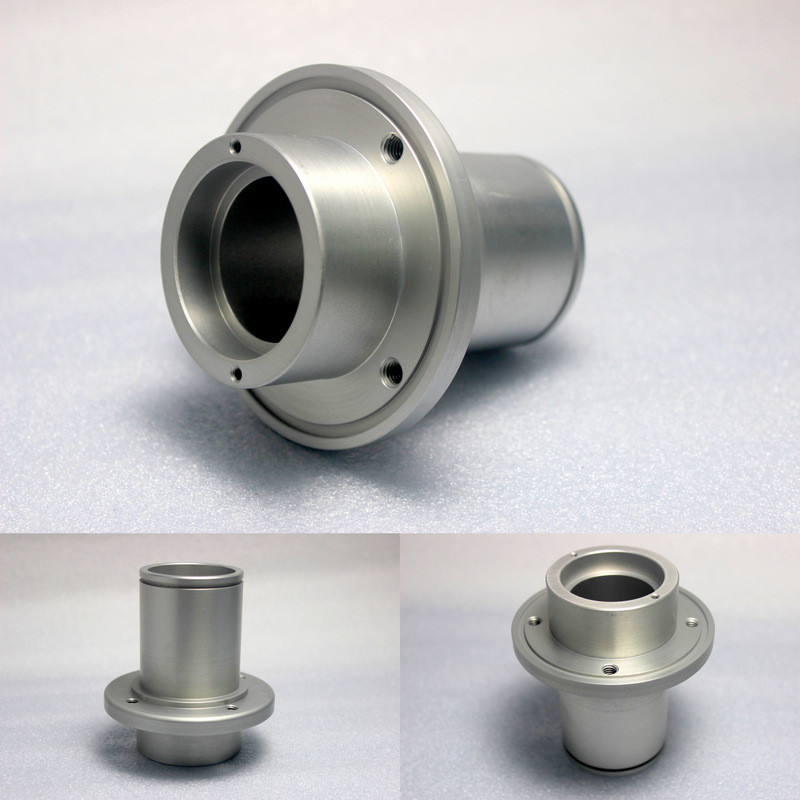

Product Description

Stainless steel is generally composed of iron, chromium, carbon and other elements.

2 series: horse element + manganese alloy, 3 series: austenite + nickel alloy, 4 series: ferrite + carbon alloy

Stainless steel for household products can be divided into 4 and 3 series, 430 (18-0), 304 (18-8), 316 (18-10).The number in front of the code indicates the chromium content, and the number behind represents the nickel content.

430 stainless steel (18-0) : iron +18% above chromium nickel free, can prevent the oxidation caused by natural factors, called stainless steel, jis code for 430, so called 430 stainless steel. Unable to resist the oxidation caused by chemical substances in the air, 430 stainless steel is not often used for a period of time, will still have oxidation (rust) due to unnatural factors. Series 4 belongs to carbon-containing stainless steel, with hardness higher than series 2 and 3 and corrosion resistance lower than series 3.

304 stainless steel (18-8) : iron +18% chromium +8% nickel, can resist chemical oxidation, this stainless steel is no. 304 in jis code, so it is also known as 304 stainless steel; 304 is the material that must be used in the national standard of pressure cooker, and the standard material of stainless steel pressure cooker is above 304 ( because the pressure cooker has the national standard of material, which is made to prevent the pressure cooker from exploding, and the material is also standardized by the way ).

(18-10) : but the chemical composition of the air is more and more, some places with more serious pollution even 304 will have rust; So some high-end products will use +18% chromium +10% nickel to make, in order to make it more durable and corrosion resistant, no metal ions precipitation, this stainless steel is called 18-10 stainless steel. Some of the tableware instructions are similar to "use 18-10 state of the art medical stainless steel".

This is non-toxic stainless steel, or standard grade stainless steel. The simplest way to tell is to use a magnet to draw on the bottom, which is 430 and 304, which is weak or weak. [1] however, most of the 304 pot now has a layer of 420 magnetic conductivity layer, which is magnetic, so the magnet detection is not accurate, the front and back ends of the spoon, sometimes can absorb, because of the magnetic polishing. So the most accurate way is to suction bottom, the most accurate detection or detection with N8 stainless steel potion.

201 (nickel content 2%, phosphorus and strong, medium precipitation), magnetic.

202 (nickel content 4%, phosphorus and strong, light precipitation), almost no magnetic.

MAIN PARAMETER

Material | Carbon Steel, Stainless Steel, Aluminium Alloy, Brass, Copper, Bronze, Plastic, Titanium Alloy etc |

Processing Scope | CNC Machining, Turning, Milling, Drilling, Punching, Stamping |

Size | Can be customized for different demands |

High Precision | +/-0.01mm |

Press | From 5MT to 600MT |

Surface Treatment | Zinc/Chrome/Nickel/Gold Plated, Polishing, Anodized in all colors, Power-coating etc |

Application Field | Medical Device Parts |

Minimum Order | 100pcs |

Delviery time | 10-35 working days depends on order quantity |

Port | Dongguan |

Regular Packing | Inner Plastic bag and foam, outer carton box |