Automation Equipment Parts

-

CNC Turning Parts Custom Parts

Our advantages for customers to customize, cost-effective processing solutions

Send Email Details

• precision CNC machining meets customer requirements

• complete CNC production, including precision CNC milling and turning

• complex processing, assembly, welding, etc

• short run and fast lead time

OEM for prototypes and bulk orders

Hexiang specializes in providing one-stop service for automatic equipment parts processing, from raw materials to production and delivery of quality control, to ensure customer satisfaction is the first element of our service. -

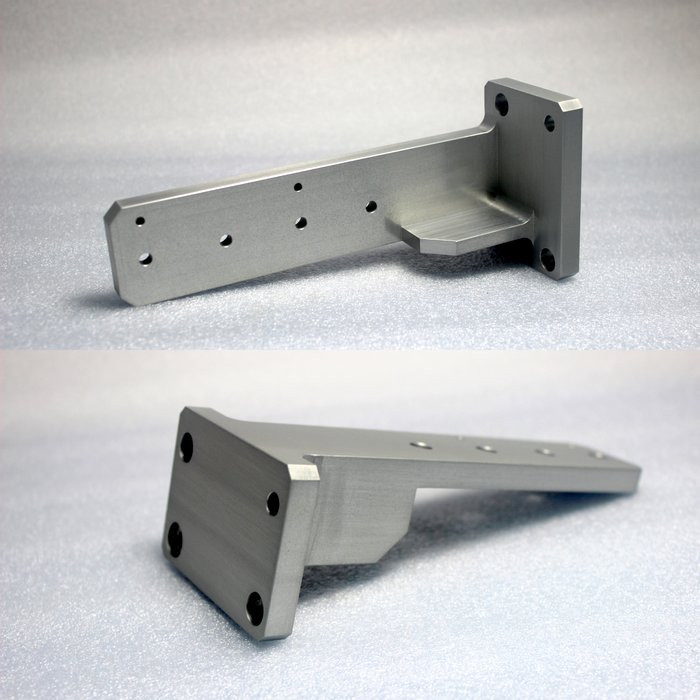

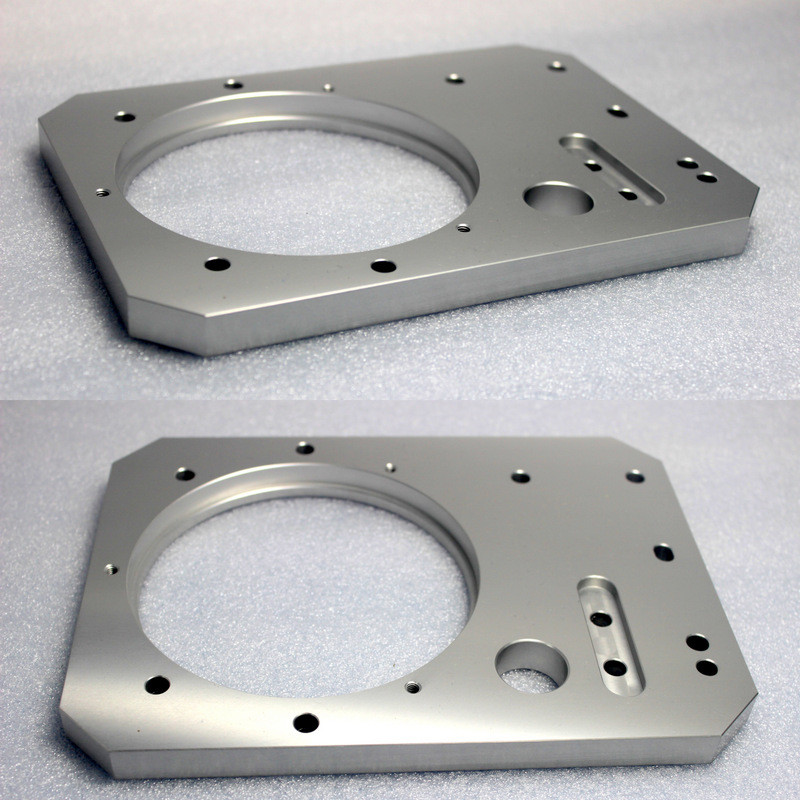

Milling Parts Aluminum Hard Anodize

Our advantages for customers to customize, cost-effective processing solutions

Send Email Details

• precision CNC machining meets customer requirements

• complete CNC production, including precision CNC milling and turning

• complex processing, assembly, welding, etc

• short run and fast lead time

OEM for prototypes and bulk orders -

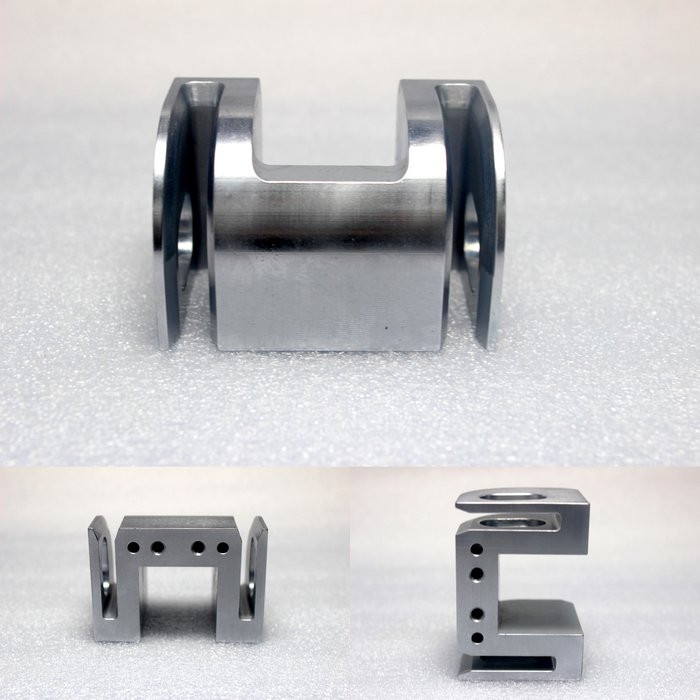

Milling Parts Stainless Steel Precision

Custom, cost-effective machining solutions

Send Email Details

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

100% inspection of critical dimensions by caliper, micrometer, height gauge, projector, CMM, and other test equipments like hardness tester, roughness tester, film thickness tester, plug and thread gauges, etc.

The capabilities of our CNC machine shop that enable our precision manufacturing custom cnc machined parts with highly accuracy as per your design drawings, We also do assembly, fixture engineering design and fabrication for customers’convenience. -

Turned Parts High Precision

Our advantages for customers to customize, cost-effective processing solutions

Send Email Details

• precision CNC machining meets customer requirements

• complete CNC production, including precision CNC milling and turning

• complex processing, assembly, welding, etc

• short run and fast lead time

OEM for prototypes and bulk orders

Hexiang specializes in providing one-stop service for automatic equipment parts processing, from raw materials to production and delivery of quality control, to ensure customer satisfaction is the first element of our service. -

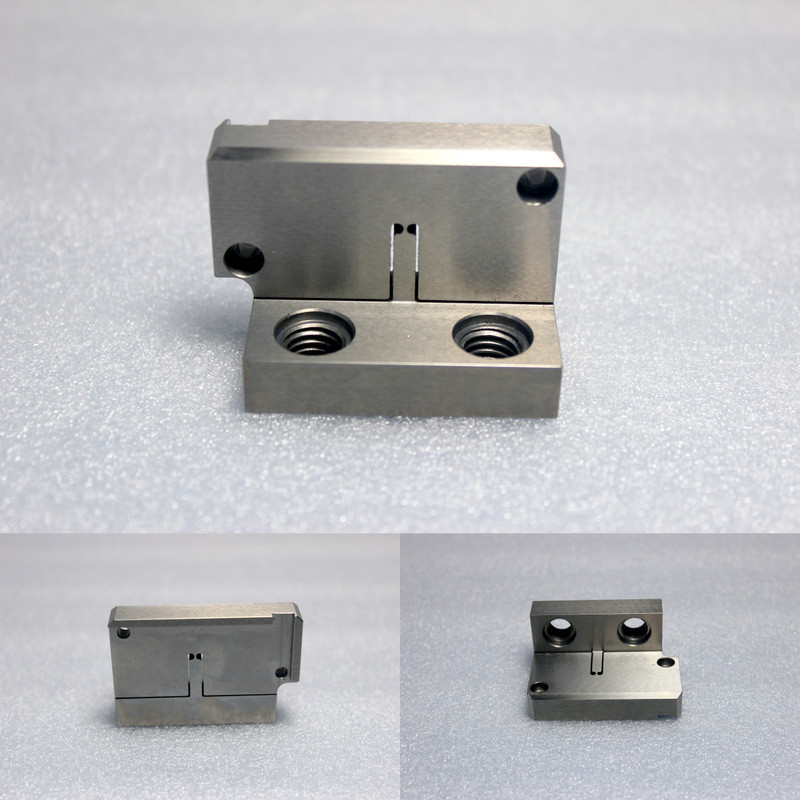

CNC Precision Machining Parts Steel

Advantages of stainless steel:

Send Email Details

1. High strength, good plasticity and toughness.

2. Uniform material and high working reliability.

3. Steel is weldable.

4. Steel has no leakage, easy to make a closed structure.

5. According to different strength requirements, steel parts are widely used in various industries.

Our advantages for customers to customize, cost-effective processing solutions

• precision CNC machining meets customer requirements

• complete CNC production, including precision CNC milling and turning

• complex processing, assembly, welding, etc

• short run and fast lead time

OEM for prototypes and bulk orders -

Hot

Turned Components Aluminum Parts

• Aluminum is light; its density is only one-third that of steel.

Send Email Details

• Aluminum is resistant to weather, common atmospheric gases, and a wide range of liquids.

• Aluminum can be used in contact with a wide range of foodstuffs.

• Aluminum has a high reflectivity and, as a result, is employed in a number of decorative applications.

• Aluminum alloys can equal or even exceed the strength of normal construction steel.

• Aluminum has high elasticity, which is an advantage in structures under shock loads.

• Aluminum keeps its toughness down to very low temperatures, without becoming brittle like carbon steels.

• Aluminum is easily worked and formed; it can be rolled to very thin gauges.

• Aluminum conducts electricity and heat nearly as well as copper. -

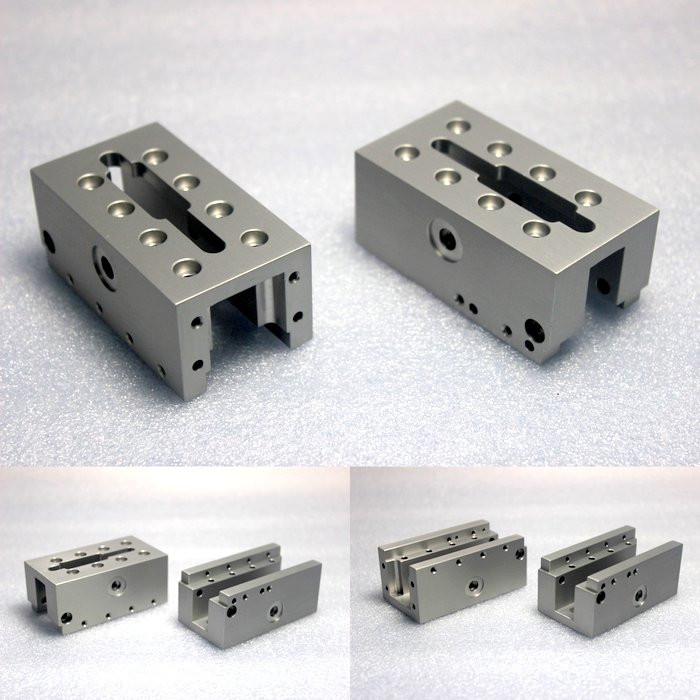

Milled Components Aluminum Parts

• Aluminum is light; its density is only one-third that of steel.

Send Email Details

• Aluminum is resistant to weather, common atmospheric gases, and a wide range of liquids.

• Aluminum can be used in contact with a wide range of foodstuffs.

• Aluminum has a high reflectivity and, as a result, is employed in a number of decorative applications.

• Aluminum alloys can equal or even exceed the strength of normal construction steel.

• Aluminum has high elasticity, which is an advantage in structures under shock loads.

• Aluminum keeps its toughness down to very low temperatures, without becoming brittle like carbon steels.

• Aluminum is easily worked and formed; it can be rolled to very thin gauges.

• Aluminum conducts electricity and heat nearly as well as copper.

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order -

Milled Components Non-standard Parts

Due to the universality of its products, non-standard automation equipment is also extensive in its application. The main application industries include the following five categories:

Send Email Details

1. The manufacture and installation of automobile parts in the automobile manufacturing industry;

2. Production, transportation and packaging of the food industry;

3. Electronic and electrical production line product delivery;

4. Warehousing equipment in the logistics industry is also widely used;

5. Application of assembly industry in processing manufacturing industry. -

Turned Components Precision Parts

Custom, cost-effective machining solutions

Send Email Details

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

We use various types of inspection equipment including an projector, digital height gauges and various other universal measuring equipment to continuously monitor and control our manufacturing accuracy. We perform set-up, in-process and final inspections to ensure that the parts we produce meet your requirements the first time.