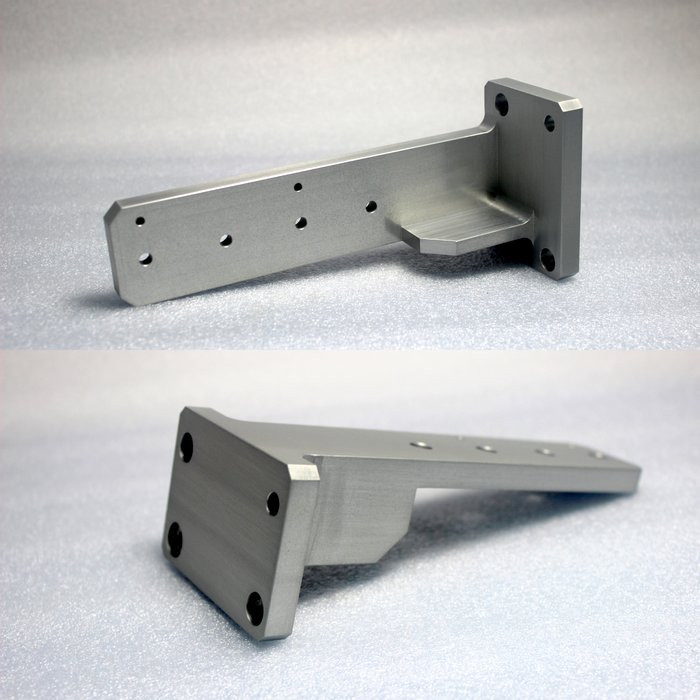

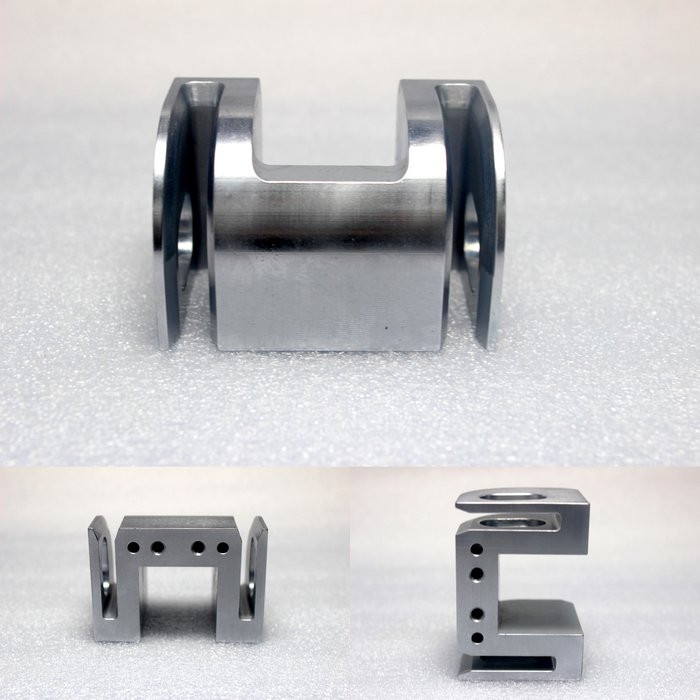

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

We use various types of inspection equipment including an projector, digital height gauges and various other universal measuring equipment to continuously monitor and control our manufacturing accuracy. We perform set-up, in-process and final inspections to ensure that the parts we produce meet your requirements the first time.

Product Description

Due to the universality of its products, non-standard automation equipment is also extensive in its application. The main application industries include the following five categories:

1. The manufacture and installation of automobile parts in the automobile manufacturing industry;

2. Production, transportation and packaging of the food industry;

3. Electronic and electrical production line product delivery;

4. Warehousing equipment in the logistics industry is also widely used;

5. Application of assembly industry in processing manufacturing industry.

MAIN PARAMETER

Material | Carbon Steel, Stainless Steel, Aluminium Alloy, Brass, Copper, Bronze, Plastic, Titanium Alloy etc |

Processing Scope | CNC Machining, Turning, Milling, Drilling, Punching, Stamping |

Size | Can be customized for different demands |

High Precision | +/-0.01mm |

Press | From 5MT to 600MT |

Surface Treatment | Zinc/Chrome/Nickel/Gold Plated, Polishing, Anodized in all colors, Power-coating etc |

Application Field | Automation Equipment Parts |

Minimum Order | 100pcs |

Delviery time | 10-35 working days depends on order quantity |

Port | Dongguan |

Regular Packing | Inner Plastic bag and foam, outer carton box |

Hexiang Precision Machinery Ltd has mature experience in the production and processing of various parts in the field of automation equipment.

Advantage:

1. Hexiang is specialized in doing OEM/ODM precise products according to customers drawings or samples

2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

3. Certificates: ISO 9001:2008

4. Fast delivery

5. 10-year machining experience, using high quality raw materials, 100% quality inspection before delivery

6. Advanced equipment, excellent R&D teams and strict quality control system

So, we can achieve Competitive price with good qualit, low MOQ and short lead time.