Since entering the new century, the trend of economic globalization is more and more obvious. The integration of world economy promotes the rapid development of electronic engineering technology to some extent. With the application of electronic engineering technology in the field of medicine, engineering management, electric power system and People's Daily life, higher requirements have been put forward for our precision parts processing enterprises. It is the core competitiveness of hexiang precision co., ltd. to continuously adapt to the market requirements and increase the investment in technology and research and development.

Product Description

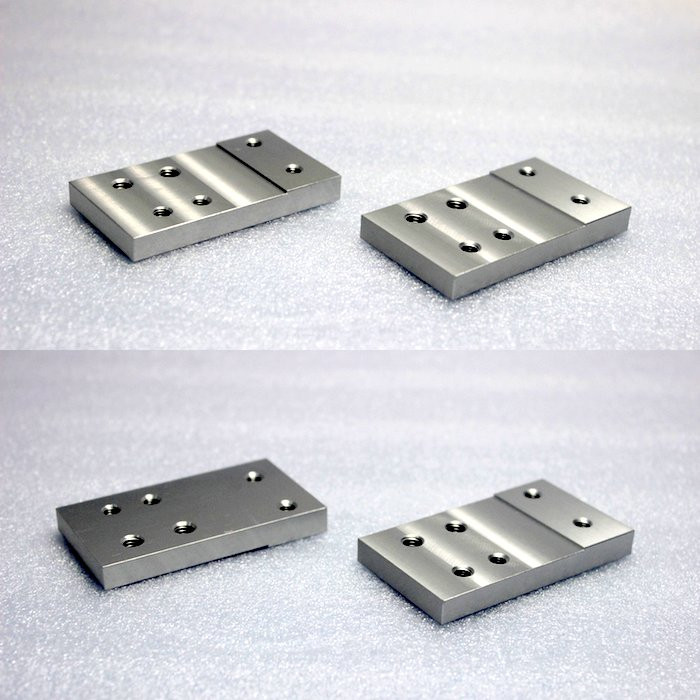

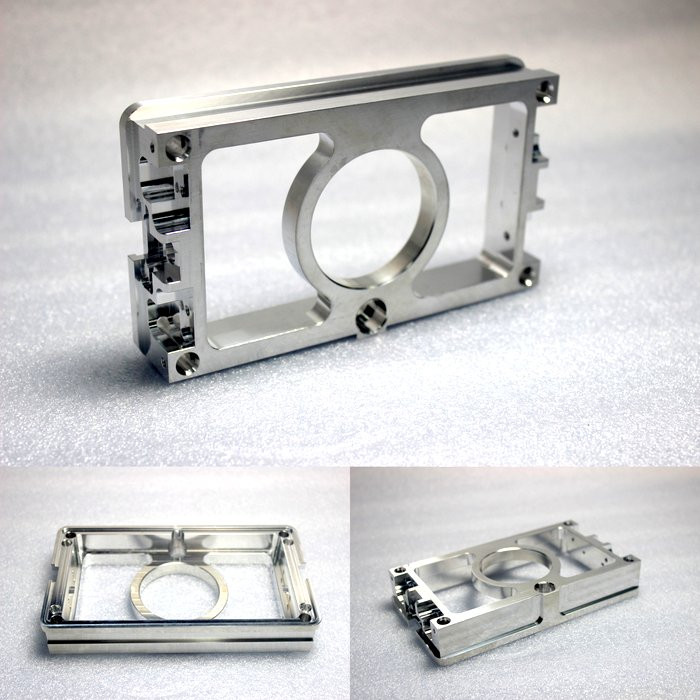

In the field of medicine, engineering management, power system and People's Daily life, a variety of instruments and tools, all need to use electronic engineering parts precision processing production.

Through milling, cutting, grinding and other processes, with the use of standardized work flow, each process needs to control the quality.

Our products, there is no fixed standard, belong to custom processing varieties. Through the Internet channels, to provide professional parts precision processing services for customers around the world.

MAIN PARAMETER

Material | Carbon Steel, Stainless Steel, Aluminium Alloy, Brass, Copper, Bronze, Plastic, Titanium Alloy etc |

Processing Scope | CNC Machining, Turning, Milling, Drilling, Punching, Stamping |

Size | Can be customized for different demands |

High Precision | +/-0.01mm |

Press | From 5MT to 600MT |

Surface Treatment | Zinc/Chrome/Nickel/Gold Plated, Polishing, Anodized in all colors, Power-coating etc |

Application Field | Electronic Engineering Parts |

Minimum Order | 100pcs |

Delviery time | 10-35 working days depends on order quantity |

Port | Dongguan |

Regular Packing | Inner Plastic bag and foam, outer carton box |

Advantage:

1. Hexiang is specialized in doing OEM/ODM precise products according to customers drawings or samples

2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

3. Certificates: ISO 9001:2008

4. Fast delivery

5. 10-year machining experience, using high quality raw materials, 100% quality inspection before delivery

6. Advanced equipment, excellent R&D teams and strict quality control system

So, we can achieve Competitive price with good qualit, low MOQ and short lead time.