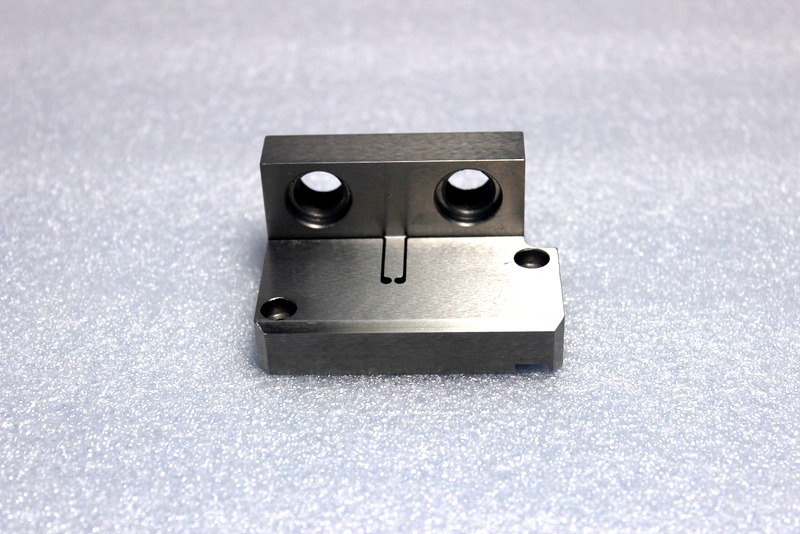

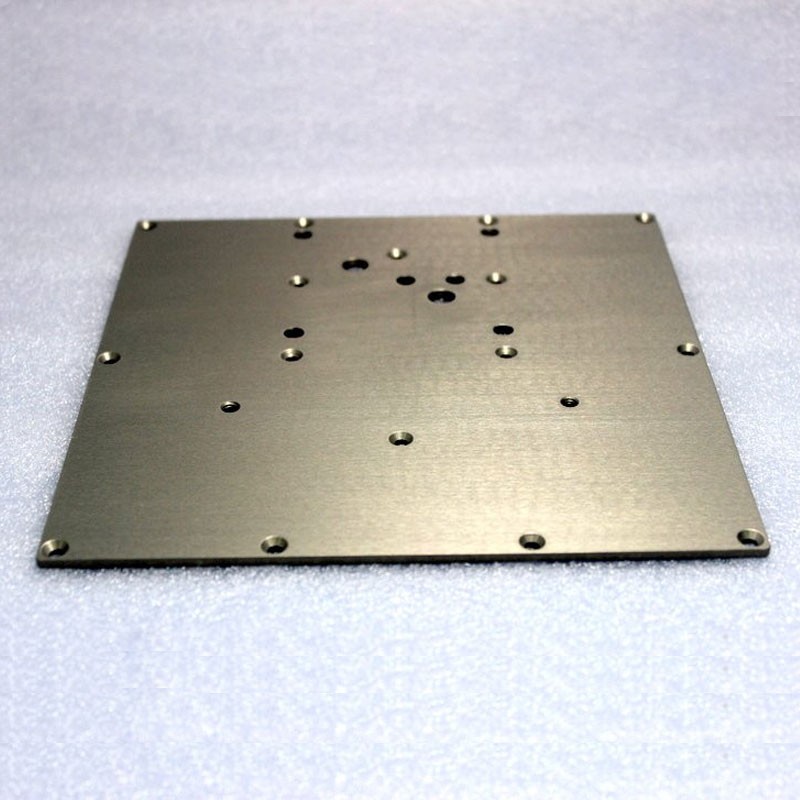

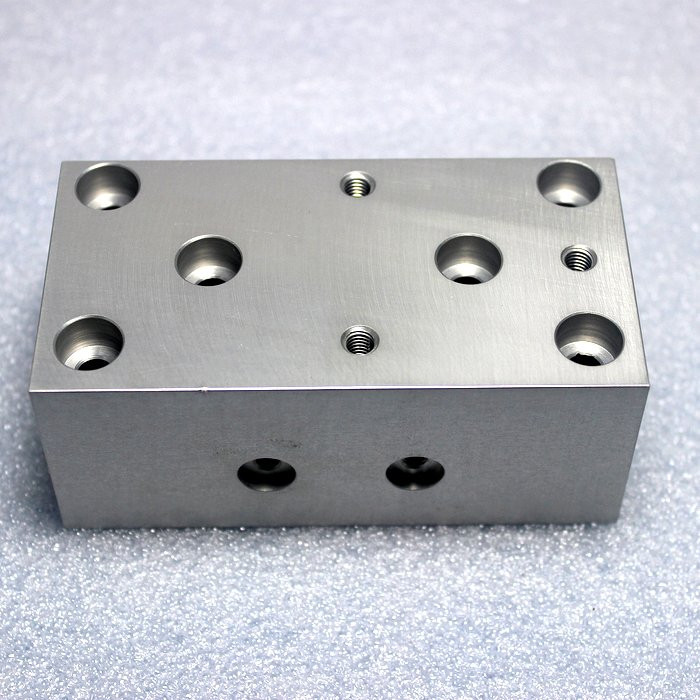

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

Surface treatment is a process method to artificially form a surface layer on the surface of the substrate which has different mechanical, physical and chemical properties from the substrate. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For the metal castings, our common surface treatment methods are mechanical polishing, chemical treatment, surface heat treatment, spraying surface, surface treatment is to clean the surface of the workpiece, cleaning, deburring, deoiling, deoxidizing skin.

Product Description

Mechanism of nitriding

Nitriding is a heat treatment in which the workpiece is put into a medium containing a large number of active nitrogen atoms and the nitrogen atoms are infiltrated into the surface of the steel under a certain temperature and pressure to form a nitrogen-rich hardening layer.

Nitriding

1. Nitriding can make the surface of parts have higher hardness and wear resistance. For example, the surface hardness of parts made of 38CrMoAlA steel after nitriding treatment can reach HV=950 -- 1200, equivalent to HRC=65 -- 72, and the high strength and wear resistance after nitriding can be maintained at 500 -- 600℃ without significant changes.

2. Nitriding can improve the anti-fatigue ability. Due to the formation of greater compressive stress in the nitriding layer, the parts show higher fatigue limit and lower notch sensitivity under the action of alternating load. The fatigue limit of the nitriding workpiece can be increased by 15-35%.

3. Nitriding improve the corrosion resistance of the workpiece, because the nitriding on the surface of the workpiece to form a layer of dense, high chemical stability layer, in water vapor and alkaline solution has high corrosion resistance, this nitriding method is simple and economical, can replace the galvanized, blue, and other chemical coating treatment. In addition, some die after nitriding, not only can improve wear resistance and corrosion resistance, but also can reduce the mold and parts of the adhesion phenomenon, extend the working life of the mold.

He Xiang provide metal precision machining services of non-standard to customers in a wide range of industries, from selection of raw materials and process methods, to surface treatment and safety shipping.

Advantage:

1. Hexiang is specialized in doing OEM/ODM precise products according to customers drawings or samples

2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

3. Certificates: ISO 9001:2008

4. Fast delivery

5. 10-year machining experience, using high quality raw materials, 100% quality inspection before delivery

6. Advanced equipment, excellent R&D teams and strict quality control system

So, we can achieve Competitive price with good qualit, low MOQ and short lead time.