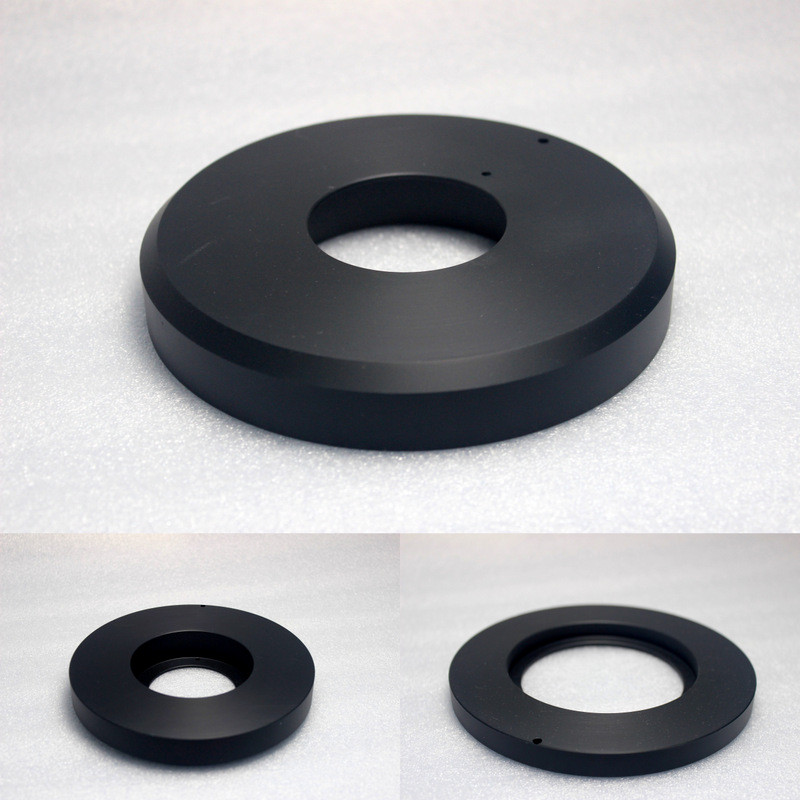

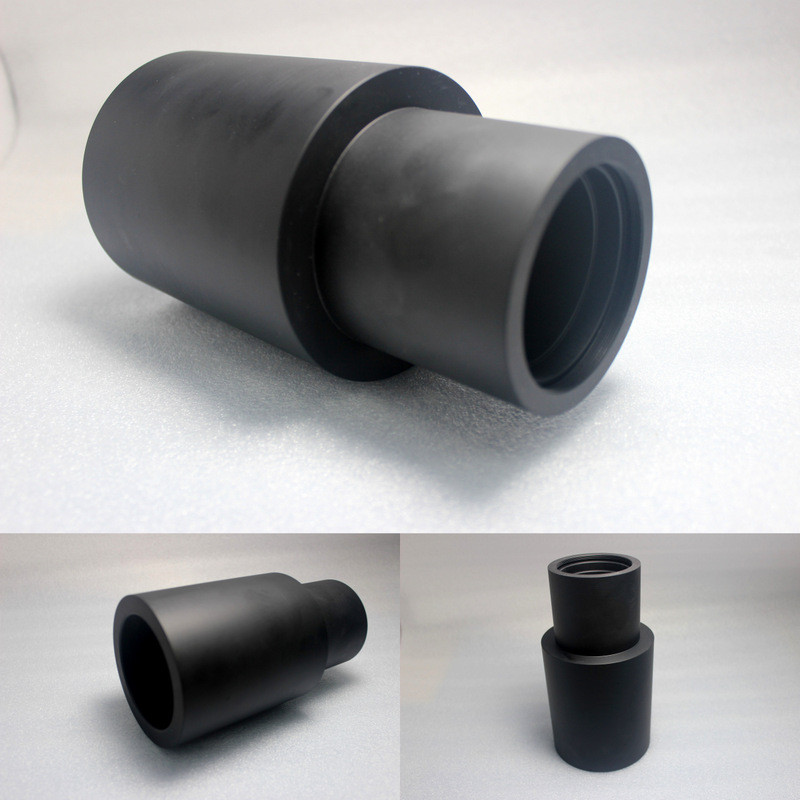

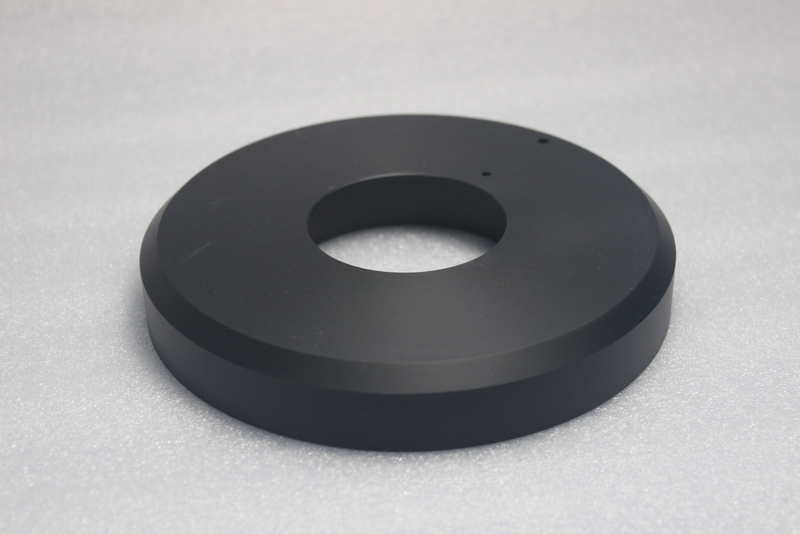

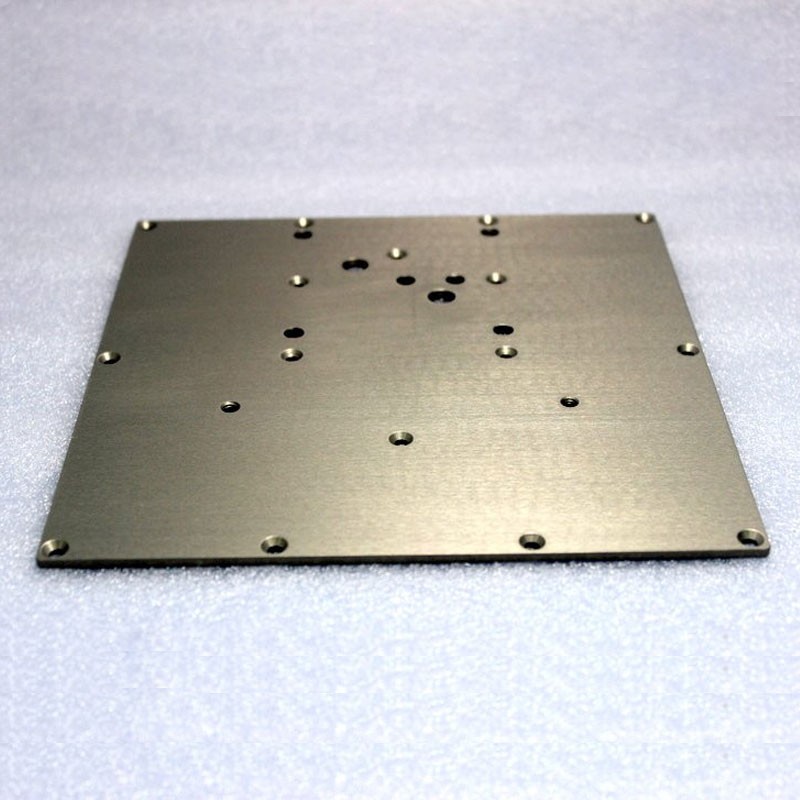

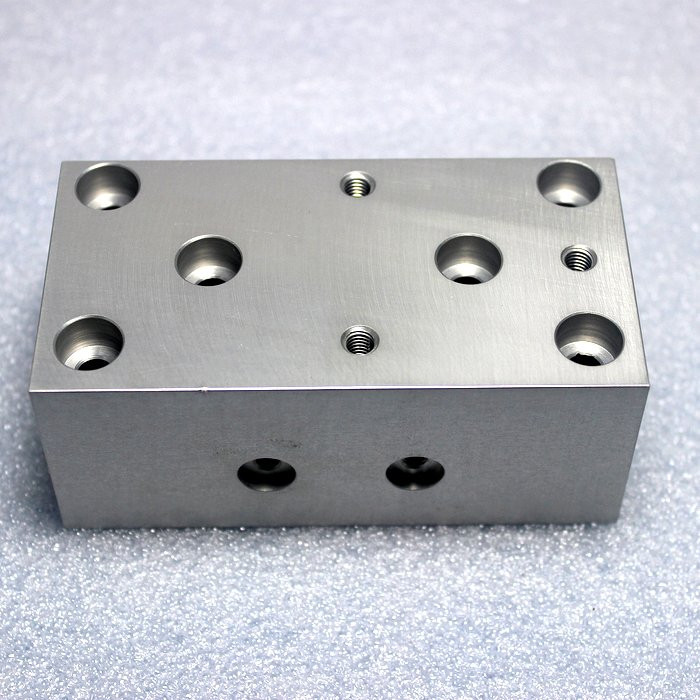

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

Surface treatment is a process method to artificially form a surface layer on the surface of the substrate which has different mechanical, physical and chemical properties from the substrate. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For the metal castings, our common surface treatment methods are mechanical polishing, chemical treatment, surface heat treatment, spraying surface, surface treatment is to clean the surface of the workpiece, cleaning, deburring, deoiling, deoxidizing skin.

Product Description

Anodizing of aluminum is a process in which a metal is placed in electrolyte as an anode to form an oxidation film of tens to hundreds of microns on the surface of the metal. The formation of this film makes the metal resistant to corrosion and abrasion.

Aluminium and aluminium alloy workpiece surface oil removal after pretreatment, as anode, other aluminum plate as cathode, with dilute sulphuric acid (or chromic acid) solution as electrolyte. After electrify, anode reaction is OH - discharge oxygen precipitation, it quickly and anodic aluminum oxide generated, and release a large amount of heat, namely the oxide film in the process of anodic oxidation, near the side of the electrolyte of Al2O3 and from Al203 H20, hardness is lower. Due to the uneven film and acidic electrolyte effect on membrane dissolved, formed a loose hole, porous layer is generated. Reach the surface of the aluminum electrolyte through pine hole, The oxidation film on aluminum matrix is continuously grown.

The oxide film obtained anodic oxidation combined with metal crystal and firm, thus greatly improving the metal and its alloy corrosion resistant ability, and can improve the resistance of the surface and enhance the insulation performance. Can be done after oxidation of aluminium wire motor shaft transformer winding coil. In addition, because the metal aluminium oxide film has porous, adsorption performance is strong, and thus can be infected with all sorts of bright colors, for decoration aluminium. For don't need to stain the surface of the pore, is to be closed, shrink pore, improve the oxidation film corrosion resistance, prevent corrosion caused by corrosive medium into the hole.

He Xiang provide metal precision machining services of non-standard to customers in a wide range of industries, from selection of raw materials and process methods, to surface treatment and safety shipping.

Welcome customers to consult.

Advantage:

1. Hexiang is specialized in doing OEM/ODM precise products according to customers drawings or samples

2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

3. Certificates: ISO 9001:2008

4. Fast delivery

5. 10-year machining experience, using high quality raw materials, 100% quality inspection before delivery

6. Advanced equipment, excellent R&D teams and strict quality control system

So, we can achieve Competitive price with good qualit, low MOQ and short lead time.