Auto parts are batch processed by moulds, and the manufacture of moulds requires precision moulds and accessories for careful assembly. With the development of high efficiency and automation of automobile production, the demand of automobile mould increases, and the development of automobile industry also needs corresponding development. Not only automobile products, but also many precision machinery parts and components are processed in the society's ever-changing consumer demand, and the updating cycle of products becomes gradually short and the frequency of upgrading becomes faster. In view of such a development trend, hexiang precision co., ltd. in the process of mechanical processing efforts to research and development, innovation, in the development of small batch, variety and other production and processing mode has mature experience. In this way, the processing of mechanical parts can meet the changing market demand.

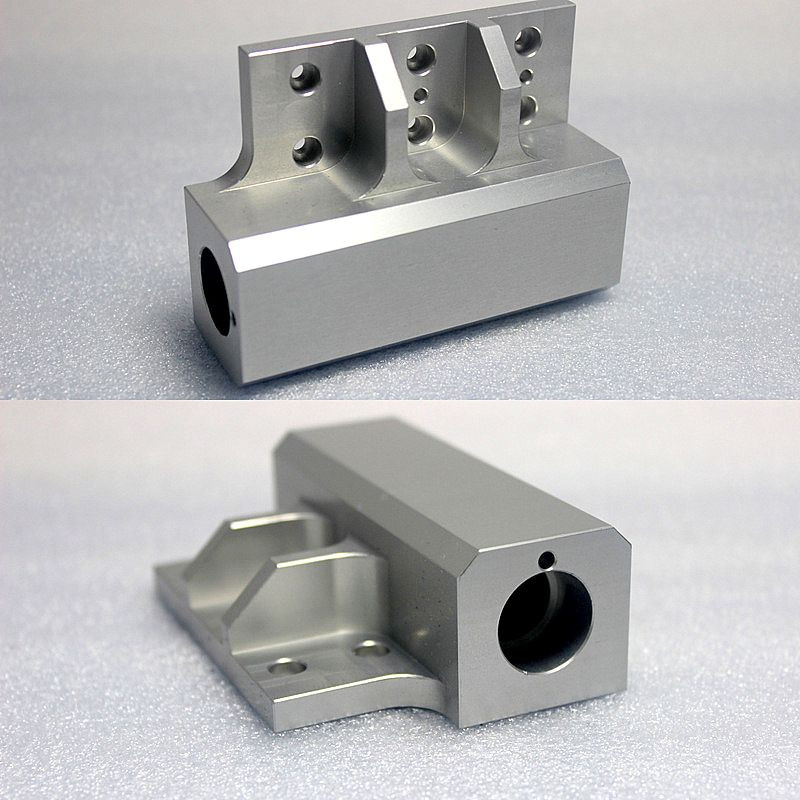

Product Description

In our daily life, the automobile has become our necessities. In the process of automobile production and manufacturing, the processing of molds and spare parts occupies a very important position. Many auto precision machinery spare parts processing and manufacturing needs to be completed with molds.

MAIN PARAMETER

| Machining Type | CNC Machining, Turning, Milling, Drilling, Punching, Stamping |

| Material | Carbon Steel, Stainless Steel, Aluminium Alloy, Brass, Copper, Bronze, Plastic, Titanium Alloy etc |

| Size | Can be customized for different demands |

| High Precision | +/-0.01mm |

| Press | From 5MT to 600MT |

| Surface Treatment | Zinc/Chrome/Nickel/Gold Plated, Polishing, Anodized in all colors, Power-coating etc |

| Application Field | Auto parts |

| Minimum Order | 100pcs |

| Delivery Time | 10-35 working days depends on order quantity |

| Regular Packing | Inner Plastic bag and foam, outer carton box |

Advantage:

1. Hexiang is specialized in doing OEM/ODM precise products according to customers drawings or samples

2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

3. Certificates: ISO 9001:2008

4. Fast delivery

5. 10-year machining experience, using high quality raw materials, 100% quality inspection before delivery

6. Advanced equipment, excellent R&D teams and strict quality control system

So, we can achieve Competitive price with good qualit, low MOQ and short lead time.